10 Best Roofing Underlayment Materials 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Grace Self Adhering Ice and Water Shield Roof Underlayment HT (G77511)

Most important from

10 reviews

The Grace Self Adhering Ice and Water Shield HT is designed to offer robust protection for your roof. Made from aggressive rubberized asphalt combined with a polyethylene film, it provides excellent adhesion, ensuring it stays firmly in place. With a thickness of 40 mils, it offers substantial durability and strength, evidenced by a tensile strength of 250 psi. This material is high temperature resistant, making it suitable for areas experiencing extreme heat, and its water resistance capability helps in preventing leaks, adding an extra layer of protection to your roofing structure.

The UV resistance feature ensures that the material does not degrade quickly under constant sun exposure, which is crucial for maintaining its structural integrity over time. One significant advantage is its slip-resistant nature, which makes installation safer and more manageable for workers. The roll measures 66.6 feet in length and 36 inches in width, covering approximately 200 square feet.

While the weight of 62 pounds may make handling a bit cumbersome, the self-adhering feature simplifies the installation process, as no additional adhesives are necessary. Suitable for various roofing projects, the Grace Self Adhering Ice and Water Shield HT seems like a reliable choice if you need a durable and high-performing underlayment material.

Most important from

10 reviews

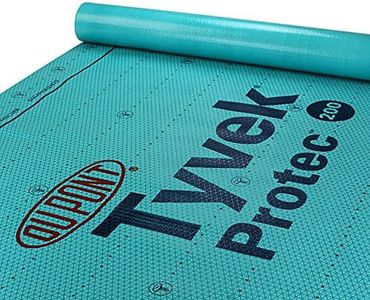

ZIP System Peel and Stick Underlayment | Waterproof Ice and Water Barrier Roof Underlayment (High Temp)

The ZIP System Peel and Stick Underlayment is a high-performance roofing underlayment designed to protect areas vulnerable to leaks or water damage, such as eaves, valleys, or entire roofs.

Made from self-adhered rubberized asphalt, it effectively seals around nails, providing robust water resistance and an additional layer of protection against ice dams and wind-driven rain. Its slip-resistant surface makes it easier and safer to apply, which is a significant advantage for DIY enthusiasts and professional roofers alike. Additionally, it meets the code requirements for an ice barrier or roofing underlayment as per ESR-4904 standards.

One of its standout features is its high temperature tolerance, with a maximum service temperature of 260 degrees Fahrenheit, making it suitable for roofs in hot climates. However, the underlayment's thickness is not specified, which might be a consideration for those looking for a more substantial barrier. It's also relatively heavy at 51 pounds, which could make handling and installation more challenging. While it offers excellent water resistance, the product brief does not mention UV resistance, a factor that could affect its longevity if exposed to sunlight for extended periods.

Grace Select 36 in. x 195 sq. ft. Roll Roofing Underlayment (1)

Grace Select 36 in. x 195 sq. ft. Roll Roofing Underlayment stands out as a reliable option for homeowners and contractors alike. With its self-adhered and self-sealing properties, installation is straightforward and user-friendly, minimizing the effort and tools needed. At 25 mils thick, this underlayment offers a reasonable balance between durability and flexibility, making it suitable for various roofing projects. It's both lightweight and easy to handle, weighing 33 pounds, which significantly eases the installation process. The 195 square feet coverage per roll is fairly standard, making it a practical choice for medium-sized roofing areas.

One of its key strengths is its slip resistance, an important safety feature during installation. Additionally, it offers protection from UV exposure for up to 30 days, giving some buffer time in case the final roofing material installation is delayed. However, this product is best suited for temporary UV resistance and should be covered relatively quickly. It is noteworthy that the product is reroofable, meaning it can be applied over existing roofing materials, providing added convenience for certain projects. The temperature tolerance and water resistance are solid, ensuring the underlayment performs well in varying weather conditions.

Backed by CertainTeed's SureStart Warranty, it promises long-lasting protection, although the specifics of the warranty coverage should be examined by potential buyers. While it ranks #91 in Flooring Underlayments, it may not be the top choice in extremely high-demand or commercial roofing projects but is well-regarded for residential use. This underlayment is particularly beneficial for those seeking a reliable, easy-to-install option for residential roofing projects that offers good protection and safety features.